Aluminum Composite material (ACM) is under the spotlight and has been all over media since the Grenfell tower fire in London, ACM is a sandwich/laminated material with two sheets of aluminum bonded together to a core in the middle, commonly used core is Polyethylene (PE) a highly flammable material, this technology has been used to make cladding material cheap, many countries have banned the ACM with PE core since Grenfell disaster which took away 72 innocent lives in 2017.

Angelo Lucchini, professor of architectural engineering at the Politecnico Milano, said that the Grenfell cladding system was equivalent to 32,329 liters of petrol.

Stakeholders of the facade industry have a huge responsibility to supply products that are safe and sustainable, the design community and contractors also have a responsibility to choose materials that ensure the safety of building users. However, some suppliers continue to promote this dangerous ACM with a PE core for a short-term profit, which is unethical and morally wrong.

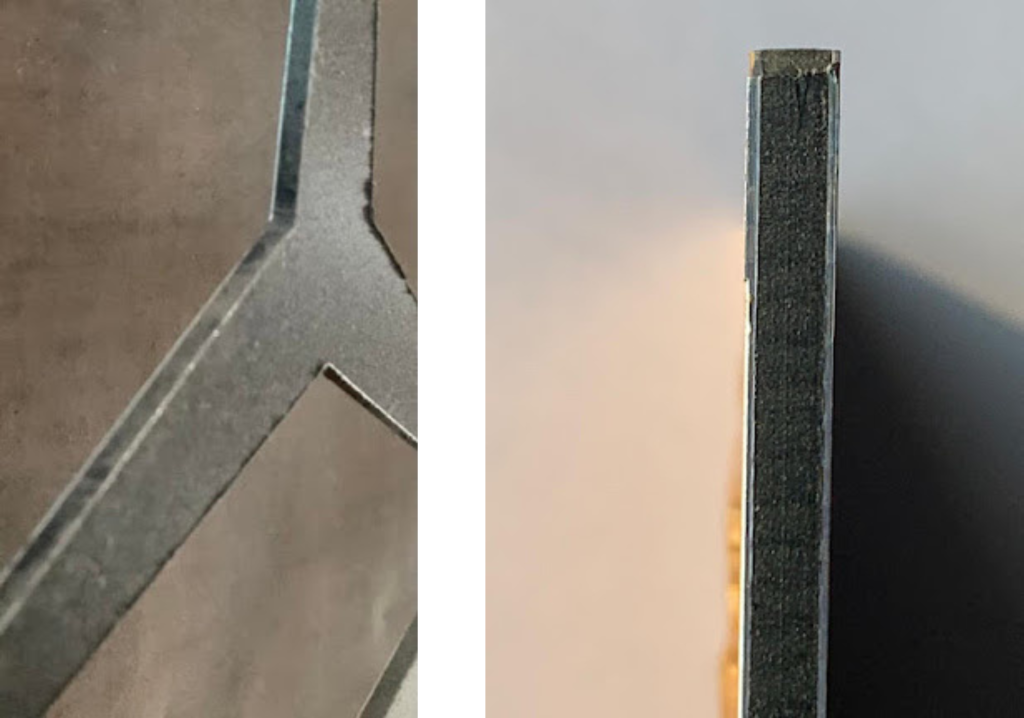

Perforated ACM material with an unattractive exposed laminate edge.

Moreover, some vendors use ACP material to perforated patterns and promote it as a facade material making things even worse. The amount of exposed edge on perforated ACM increases due to various patterns cut into a sheet, which increases fire-related accidents and puts the building users at risk. Allowing this type of practice not only tarnishes the image of the built environment of our cities but also takes the facade industry backwards.

Many countries in the region are regretting the use of ACP perforated cladding on buildings and some ended up changing it incurring huge costs. It is important we learn lessons from others mistakes.

Exposed edge corrosion

When ACM material is perforated the edges get exposed, the two images right above show the cross-section of the ACM laminated sheet with shiny outer aluminium layers and the dangerous PE core (Black) in the middle. Use of perforated ACM in an environment with high pollution, high humidity and high salt content leads to corrosion, peeling and chalking, finally, resulting in de-lamination of the sheet and air bubbles getting trapped inside the sheets resulting in swelling and unpleasant sight eventually not only put the users of the building at risk but also tarnish the reputation of the building and designer due to some vendor’s irresponsible actions.

What is the alternative?

Retail and office Building, Boudhaloka Mawatha, Colombo 04 -supplied and installed by Wallspan (Solid Aluminum Perforation)

Solid Aluminum is one possible alternative way to achieve customs design perforation on facades, which is Non-combustible and can be recycled fully too. The coating or anodizing is mostly a post-treatment, hence the exposed edges are covered in the same color as the front of the panel helping the architects to achieve high-quality architectural finishes, as opposed to low quality and cheap-looking ACM perforations.

As an innovative and responsible facade company, Wallspan has been assisting the design community for over 7 years in Sri Lanka adding value for buildings by providing the correct technology and products to the design community enabling them to create a safe and sustainable space.

Wallspan has delivered several perforated solid aluminum facades in Sri Lanka using a solid aluminum punch and carving method, which is Non-combustible and comes with high quality coated edges to achieve the necessary standards in architecture. We believe in the ethical way to bring architectural and functional values to the built environment even when perforated customs designs are required.

Retail and office Building, Boudhaloka Mawatha, Colombo 04 – by Wallspan, Arch – MSN Architects

Office building, Walukarama Road, Colombo -03 by Wallspan

G-flock fashion store, Thalawathugoday by Wallspan

Single skin perforated facade by Wallspan

Custom designed facades bring a unique identity, but using the wrong material such as ACM perforation can ruin the aesthetic appearance and also could destroy the brand value of the client while building users in danger. At Wallspan we have taken this to a completely new level by pioneering high-quality materials such as Titanium Zinc to achieve custom design facades, which provide a design life of 60 to 80 years unparalleled to even coated solid aluminium. Our Team’s international exposure from Europe to Asia has enabled us to provide careful solutions with attention to detail to create architectural masterpieces in Sri Lanka, Indonesia, Maldives and India.

ITUM, Moratuwa University – Titanium Zinc material perforated and solid panels. DG5 Architects

Colombo Jewellery, Titanium Zinc Perforated Zinc Facade. By MICD Archiects

Wallspan’s continuous development work to find suitable facade material and technology to enhance the quality of the built environment has put us at the forefront of providing many pioneering facade materials and solutions to the architectural community in Sri Lanka, EXTEC expanded Aluminium mesh, Titanium Zinc and Living facades are names to few in our journey improve building facades. Our commitment and passion for facades have brought some interesting technology to the facade industry. The writer intends to share more knowledge with the architectural community in the Wallspan facade blog. Please visit the blog for details of our other material.

Written by: Ramzeen Rauff -Director Wallspan